Immersed in discovery: Peek into our recently occupied projects that delight visitors and are devoted to research.

With much anticipation and years of focused design and construction, PAE and Luma are honored to have been part of the teams that have designed two new buildings opening their doors, ushering in wonder, exploration, and transformative experiences.

THE KNIGHT CANCER RESEARCH BUILDING

Is there a higher calling than curing cancer?

In the main entry of The Oregon Health & Sciences University, Knight Cancer Research Building, in Portland, OR, this question beckons to all who enter. It is a reminder of the mission of the institute: to detect cancer earlier, improve the health and morale of patients, and end cancer as we know it. In the spirit of collaboration, the Knight Cancer Research Building will house 650 elite, multidisciplinary scientific researchers – pioneers in personalized cancer care – doing what they do best: find cures.

This exciting and innovative project used an Integrated Project Delivery (IPD) method with co-location to maximize the creativity of the design, and increase design and construction efficiency, with the whole team. Alongside the SRG Partnership, PAE helped make this 320,000 square foot, LEED Platinum building a victorious design process and space for innovation. To achieve the high sustainability goals of the project, PAE’s design utilized heat recovery chillers, radiant slabs and a lab exhaust fan control system based on wind conditions. Additionally, a rainwater reclamation system takes advantage of Portland’s abundant water supply and uses rainwater collected on site to flush toilets. The innovative, 7-story building saves over 35-percent more energy than a typical code building and houses wet labs, research facilities, office spaces, conference and auditorium spaces, a retail restaurant shell, and a lobby on the first floor.

The lab spaces themselves were designed to be flexible and adaptive to researchers’ needs. Because the structure is post-tensioned concrete, the wide structural bay allowed for columns to be eliminated in the labs, providing space for endless movement and change. In addition to this flexibility, the overhead service carriers that provide all primary lab utilities and the moveable lab write-up desks provide even more ability for fluid adjustments.

Explorations are not only happening in the labs; new ideas are sparked with chance encounters in the halls and common spaces. The design team knew the building would be special, and as the new space surpassed their high expectations, they were grateful to be part of a team doing extraordinary work in the new research building.

THE PACIFIC SEAS AQUARIUM AT THE POINT DEFIANCE ZOO & AQUARIUM

Complex building design and construction is not only for research facilities, but also for occupants that need a different kind of care.

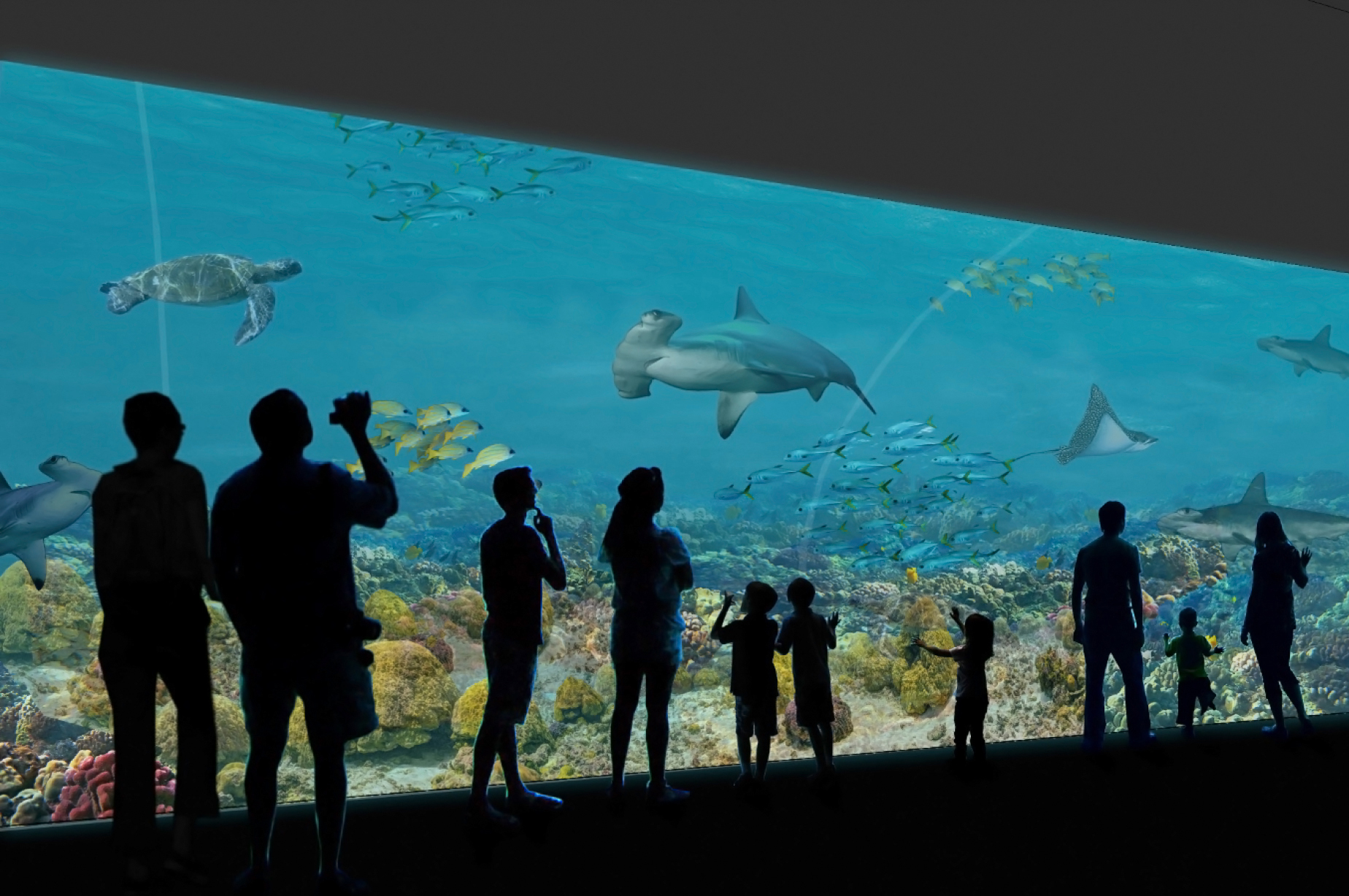

The Pacific Seas Aquarium recently opened at Point Defiance Zoo & Aquarium (PDZA), in Tacoma, WA, representing decades of dreaming and the largest capital project in the history of PDZA.

Creating a space of delight and wonder, the Pacific Seas Aquarium is like walking straight into the ocean. Surrounded by sharks, eagle rays, and sea turtles, all ages are enamored by the new 280,000-gallon exhibit, Baja Bay. With interactive exhibits and galleries at each step, this undersea journey intimately connects guests with the Puget Sound and Pacific Ocean.

Determined to find building solutions that sustain healthy aquatic habitats, maintain excellent indoor air quality and minimize energy use while meeting rising international standards, PAE collaborated with EHDD, working steadfastly with the Point Defiance Zoo & Aquarium, to design a facility that had the smallest greenhouse gas footprint possible. To help achieve these sustainability goals and develop facilities that provide excellent quality of life for the aquarium’s animals, PAE performed a life cycle cost analysis to help the owner select the aquarium’s life support system that provides heating and cooling to all exhibits while maintaining correct environmental conditions to the various exhibit types. While it sounds simple, a key goal was to avoid burning fossil fuels on site.

With this goal in mind, PAE designed high performance building systems including a 100% outside air system, a heat recovery air to water heat pump, a heat pump heat recovery run around loop, and radiant floors. The heat pump technology uses the same refrigeration cycle to extract heat from the chilled water loop, but instead of rejecting the heat to the atmosphere, it first injects the heat energy in the heating water loop when simultaneous heating and cooling occurs. These solutions help the aquarium to meet rising international standards, improving the health and safety of animals and staff alike by providing a high air exchange rate to maintain excellent indoor air quality.

Additionally, the exhibit areas and tank lighting feature LED based light sources that provide static white light, color temperature (warm or cool) tunable white light, and Red/Green/Blue/White color ranges that fully engages the public and their interaction with the underwater world, supporting the aquarium’s mission while still maintaining sustainable solutions.

These sustainable features contribute to the building’s low Energy Use Intensity (EUI), which is predicted to vary between 40 and 50 kBtu/sf/yr; when most aquariums range from 150 to as high as 500 kBtu/sf/yr.